|

General Information: |

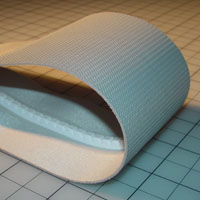

V-Guide Belting

Stiles provides belts with V-Guides for packaging equipment and many other applications demanding straight running belts.

V-Guides are just one method for guiding belts. It is not the cure all for all tracking problems. Guides are not the solution for belts which are out of alignment, or not fitted for the application.

Pulley minimum diameters are usually increased to accommodate the added guide. Notching the guides increase the flexibility and decrease the minimum pulley sizes. Guide materials also affect required pulley sizes. Suggested pulley diameter sizes can increase when surface padding is bonded to the belt. Larger pulley sizes can reduce cover and belt stress cracking, reduce cover splice failure, reduce the occurrence of delamination and increase belt life. Increased belt speed and high belt tension increase the negative affects of smaller pulley sizes.

Belts with V-Guides require pulleys and sliders with cut outs to accommodate the guide. Generally, single guides are centered on the pulley side of the belt.

The belt in the picture above is used on a bottle unscrambler. This belt will have our Slip Paw™ seamless fabric wrapped sponge cover bonded to it.

Contact Stiles for other methods of tracking your belts.

V-Guide profiles are also used as belt cleats and belt edge walls.

Note that Stiles uses V-Guides from varied manufacturers. Dimensions vary slightly with the different manufacturers and by the materials used.